Enjoy professional expertise: produce the best food

When it comes to production, those who provide for the physical well-being of millions of people have a special responsibility. Not only should a high standard of hygiene be maintained every day – the necessary climate parameters also have to be right. We develop the leading climate and process air solutions for the area of food production. When will you get a taste for it?

Efficient air conditioning and process air technology for the food industry

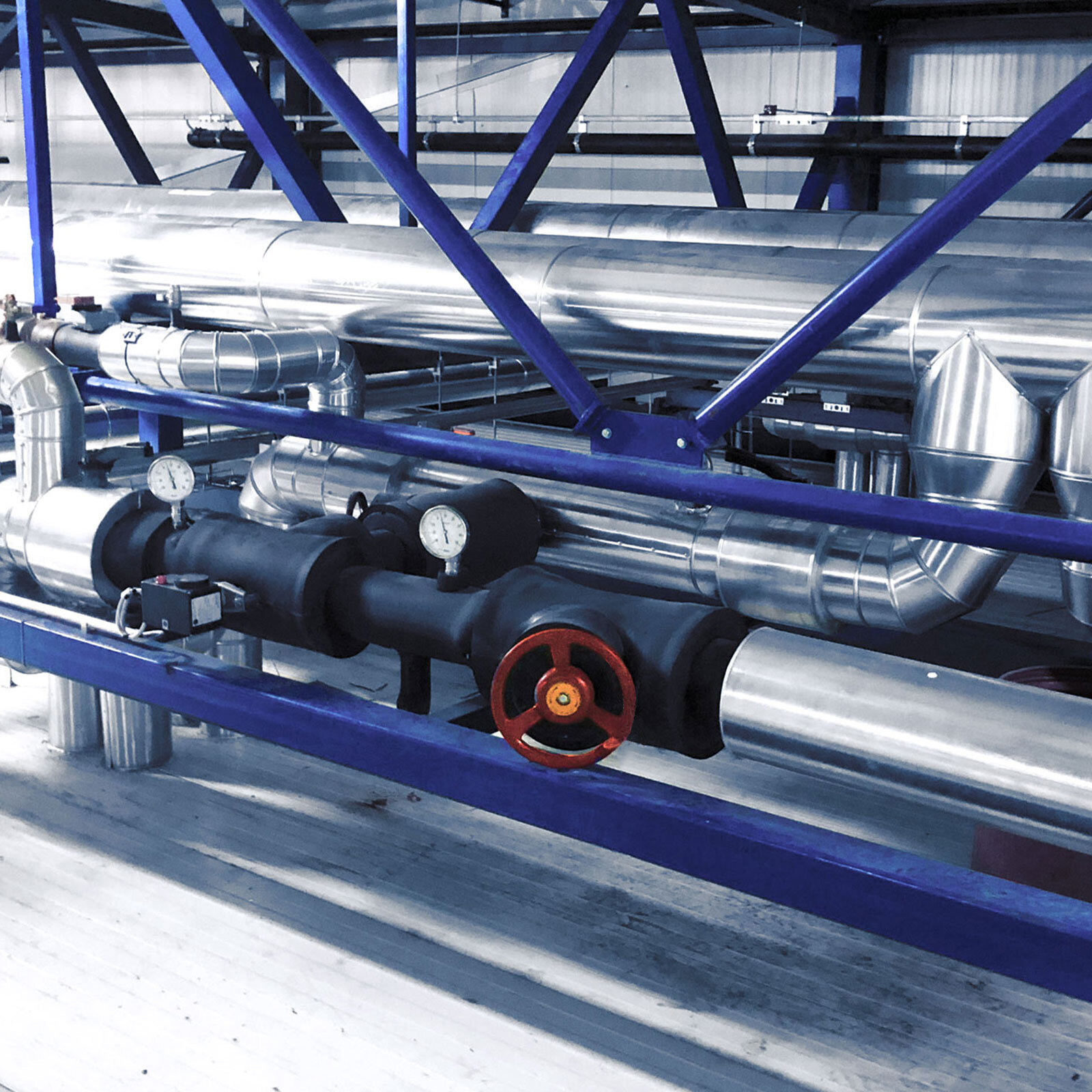

The climate conditions in the production of food aren't just a side issue. They are one of the factors that determines whether the product is successful or not. Not only do we know how cheese ripens, we also understand how to design a cooling tunnel according to your precise needs. For this purpose, we build systems that take account of every conceivable climate condition and create the best conditions for production in a low-pathogen environment. Incidentally, climate-controlled food storage is also one of our specialties.

As an international specialist for industrial air conditioning and process air technology in the food industry, we know all the requirements surrounding food production. To ensure that you can safely maintain your product quality, we offer innovative solutions that enable the highest hygiene standards, controlled hygienic indoor air conditions, the defined cooling of your products and the consistent guarantee of the required climate parameters.

With our cutting-edge systems and filter technologies, we make sure that pathogens don’t stand a chance. That means you improve the quality of your products and benefit from a longer shelf life for your food.

In the food industry, air conditioning consumes a large proportion of energy costs. We ensure energy-efficient system operations by controlling the fans as required with the use of frequency converters, self-optimizing automation modules such as the speed control of pumps, and with sliding flow temperatures in refrigeration systems.

No food production is the same as the other – which is why we develop individual air conditioning solutions for each customer.

During the production, packaging and storage of food products, in addition to the defined quality of the ambient air, constant indoor temperatures and indoor humidity levels often play an important role. These not only protect food from spoilage, but also ensure high quality products and processes.

The big names in the food industry and small-scale, specialist cheese dairies have relied on our air conditioning expertise for several years. This means that we know all about the requirements surrounding the various products and their production processes.

Why we are the right choice

The world of food production is changing every day, which means that it requires new solutions. Our experienced engineers are dedicated to providing innovative and energy-saving solutions to our customers worldwide. With a considerable amount of enthusiasm, excellent technology and industry knowledge, we rise to the challenge of your production processes, so that you can focus on the quality of your food.

Our focal points

- Air conditioning

- Hygienic air conditioning technology

- Precision air conditioning technology for cheese ripening

- Air technology for yoghurt incubators

- Ventilation systems

- Cooling tunnel systems / pallet cooling systems

- Product cooling

- Sector-specific clean room technology

- Air disinfection with UVC systems

- Filter systems Automation (measurement and control technology)

- Cooling technology

- Cold and hot water systems

- Energy-saving systems

Cheese dairies – we know how the cheese ripens

To achieve the perfect ripening climate for your cheese production, you need sophisticated systems that keep the temperature, humidity and airflow rates at a constant level – at every point in the ripening room. Our A-Bloc technology ensures that all the key conditions for cheese ripening are met at all times.

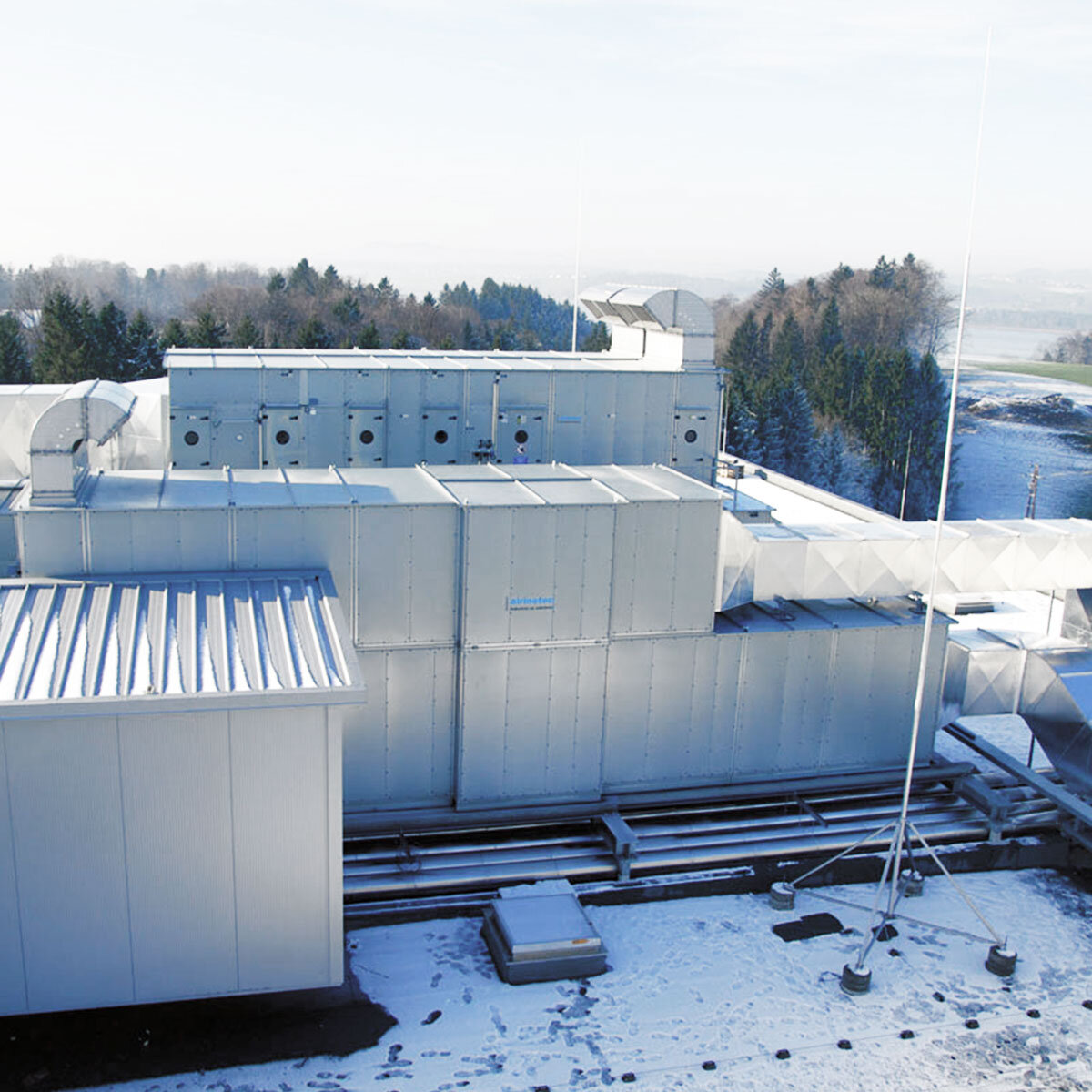

Beverages – moisture under control

Air is an important factor in the field of beverage production. During the production, in the bottling machines and in the packaging, air contaminated with pathogens can develop quickly due to the production process. It may be the case that this can also quickly contaminate the product. For this reason, it is important to ensure the optimum quality of the room air, especially in the area of the critical production processes, through the use of suitable ventilation systems. Concepts that are customized to the requirements of the beverage industry and the use of energy savings through heat recovery, combined with state-of-the-art automation and control system software, ensure low investment- and operating costs.

Vegan and plant-based foods – efficient cooling

In the production of vegan and plant-based foods, efficiency in production plays an important role, among other things. For example, tofu is cooked in an autoclave and then must be cooled down as quickly and precisely as possible. Moisture input must also be removed quickly. The systems from airinotec, for example our rapid cooling system BatchCool, help you with this and also significantly increase throughput so that your product can be processed further quickly.

Other industries – chilled, baked and well-packaged

Confectionery production, as well as the manufacturing of finished products and baked goods, are sensitive processes which are subject to strict hygiene regulations. We develop and build reliable air conditioning solutions for you, and supply the production processes with clean air during the cooling, baking and packaging. In doing so, we ensure a stable humidity level and comply strictly with the hygienic specifications, which play a key role, especially in open processes.

Project reports of food industry

Successful projects for the food industry are the best proof of confidence in our work. For many companies, we have taken on and successfully risen to a wide range of challenges surrounding air conditioning and process air technology for the food industry. In our project reports, all the details and the reasons for our success become clear through practical examples. Your challenge has probably already been solved by us!